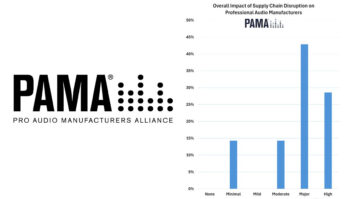

Recently, there has been much talk about supply chains being disrupted as facilities shut down around the world to help slow the spread of COVID-19, the respiratory disease caused by the novel coronavirus. It’s difficult to forecast how this will affect supply chain delivery, but my prediction is that it will be more of a hiccup than a long-term event. I expect that once manufacturers deplete their inventories, second sources will temporarily be put into action, staff will be reassigned to fill gaps, and as the virus subsides, the supply chain will eventually return to normal.

Recently, there has been much talk about supply chains being disrupted as facilities shut down around the world to help slow the spread of COVID-19, the respiratory disease caused by the novel coronavirus. It’s difficult to forecast how this will affect supply chain delivery, but my prediction is that it will be more of a hiccup than a long-term event. I expect that once manufacturers deplete their inventories, second sources will temporarily be put into action, staff will be reassigned to fill gaps, and as the virus subsides, the supply chain will eventually return to normal.

“Normal” these days can be a pretty high standard, too. Amazon has clearly nailed solutions to delivery issues on a scale that is simply unfathomable for most of us to comprehend, but for many businesses, supply chain delivery issues are a very real problem. Whether you are an end user, dealer, distributor or sound company, there is nothing more frustrating than ordering something that’s not delivered on time. Over the years, I have experienced firsthand how delivery problems can impede a business from growth and even drive management to wits’ end.

Back some 20 years ago at Radial, I decided to try to compete with Hosa, king of the low-cost cable, by importing similar products from China. What Hosa does so well is that it carries a huge assortment of solutions, making it a one-stop shop. Whether you need an RCA to 1/4-inch adapter or Y cable, Hosa can fill the order. After an exhaustive search online, I finally found a manufacturer in China that appeared like it could be the right supplier to fulfill our needs. It had a wide selection and seemed to understand the accessory cable business model, so I ordered some samples. As soon as the samples arrived, I opened the box, only to discover that they were packaged with Hosa-brand back cards. I was ecstatic! This meant I could compete with Hosa with the same quality and, I hoped, buy at a price that would enable me to match theirs. I decided to call the brand Proflex.

The biggest challenge when importing low-cost items from China is that you need to order container-loads at a time in an effort to offset the high cost of freight. We placed our first container order. Although shipping was slow, it arrived and we were able to get the ball rolling.

The one rule that always seems to apply is the 80-20 rule: 80 percent of your revenues are derived from 20 percent of your inventory. With cable, this certainly holds true. Our first order had a wide assortment of products (selection), yet within a couple of months, we had sold all of our hot-sellers. We immediately placed a second order and waited. And waited. And waited. I think the order finally shipped eight months later.

Because we could not fulfill the orders for the high-turnover items, we soon lost whatever shelf space we had gained. Suffice it to say that our little orders did not carry sufficient weight to get the factory’s attention. Hosa was likely overwhelming the manufacturer with orders. The result: We cleared out all of the Proflex cable to Guitar Center and got out of the business.

A similar delivery issue occurred with Jensen Transformers. Deane Jensen began producing transformers in the early 1970s and over the years built a tremendous reputation. Few will argue that Jensen makes the best audio transformers on the planet. Radial did more to promote Jensen than Jensen itself, and the venerable Radial JDI, which incorporates those transformers, became the cornerstone of the Radial direct box family.

The only problem with Jensen was delivery. We would order 1,000 transformers and Jensen would deliver 500. We would then have to wait a month or two to get more, and by this time, we had another 2,000 transformers on order! Before Radial came along, Jensen was a boutique manufacturer that built to order. The company simply did not have the systems in place to support the global demand that Radial had created for its Jensen-equipped direct boxes.

Because Jensen did not have the capacity to order parts in advance, they were always waiting … and putting us off, too! Without inventory, we couldn’t build products, which hugely affected our income. The problem got to the point that we had to either use other transformer manufacturers or find a way get Jensen to up their game. As soon as word got out that we had relegated certain products to other manufacturers, the market reacted fiercely, asking how we could dare make a Radial product with anything less than a Jensen. The only way to ensure secure delivery was by purchasing the company.

As a result, I negotiated a price with Bill Whitlock and immediately invested funds to increase orders and flow capacity. We updated all of the BOMs (bills of materials) so that the computer software could be used to predict part requirements and schedule deliveries. We invested in additional winding machines to increase production and then hired a full-time accountant to make sure bills would be paid on time. In no time at all, Jensen’s capacity increased and Radial deliveries got back on track.

Having control of how and when you deliver a product can have its perks. For instance, one of the easiest ways to ensure you get paid is by selling a product that people need. When a sound engineer specifies a product on a rider, the sound rental company will often go out and buy it to fill the demand if they do not have it in stock. If the rental company’s account is in arrears, they will usually pay up to ensure prompt delivery. The same applies to a retail shop. If customers are demanding a certain product and it sells regularly, they need to have it in stock or else another dealer will get the sale. No one likes to wait.

The relationships between the links in a supply chain are crucial, but they can also change over time, so it’s imperative to know where you stand in those dealings. I recall early on in our history, a dealer owed us about $30,000. This was a huge sum for us. They called saying that they needed a few more products to fill a huge order, and with this, they could in turn finally pay us. My initial thought was to hold the order until we received payment. They begged. We folded and delivered. A week later, the owner declared a staged bankruptcy and reopened a few months later as a distributor. As a small company, losing $30,000 was huge! It hurt us badly. All this to say, holding deliveries can sometimes be beneficial!

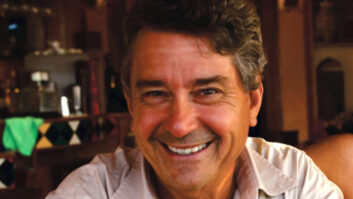

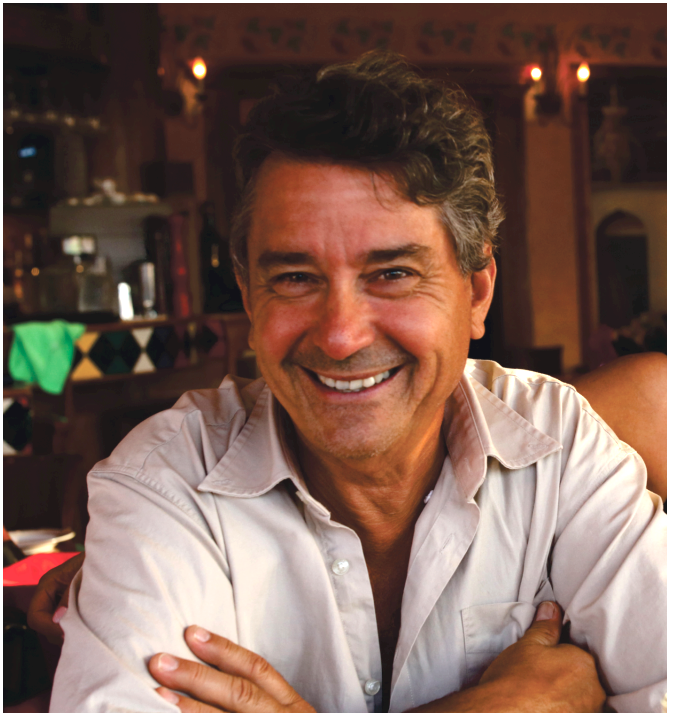

Peter Janis, former CEO of Radial Engineering, is a 40-year veteran of the music industry. Exit Plan (www.exit-plan.ca), his consulting firm, assists business owners to build their companies and prepare them for eventual sale.